COMBINE TECHNOLOGY WITH INDIVIDUALITY

When it comes to variety nothing works better than creating your own personal molds with 3d printing technology. With only a few limits concerning the later applicability as form for confectionery, the potential for customization is significant. There are numerous fields like creating special forms for certain events like exhibitions or personalising your product, create an individual jelly-shape in 3D and so on. Confectionery obtains complex shapes with a fresh new look that could not have been created that easily in any other way.

LET’ START

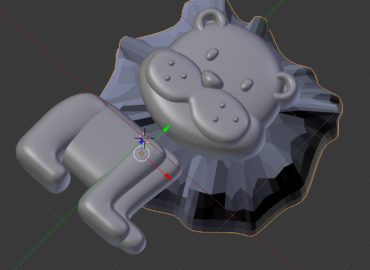

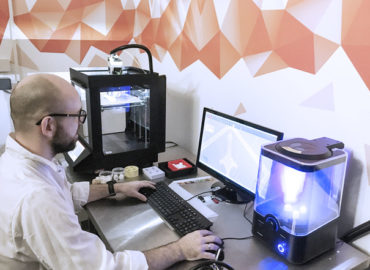

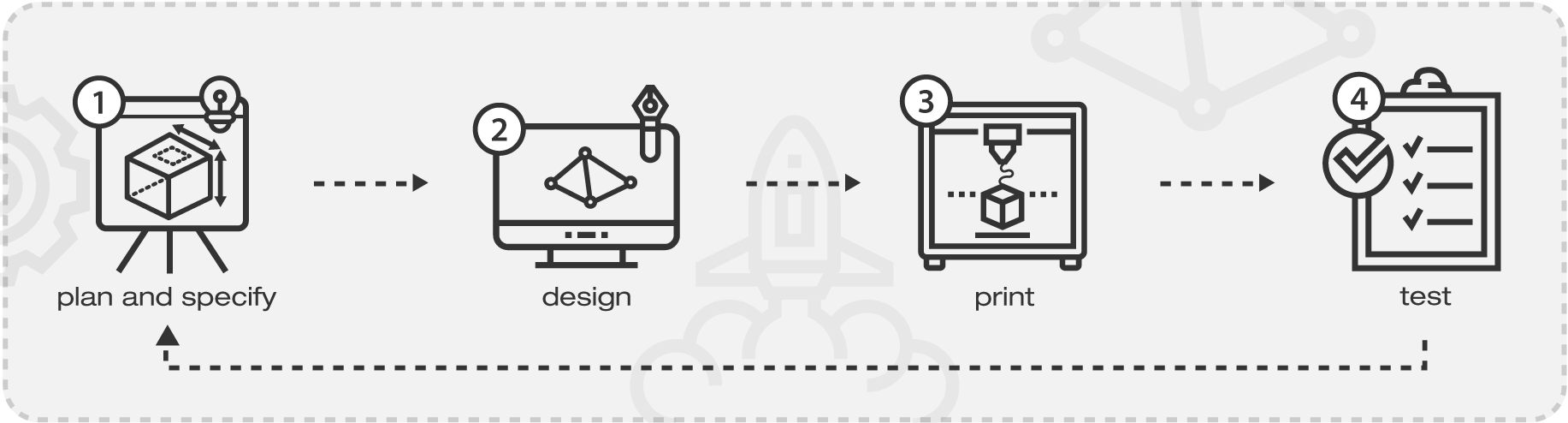

The designing process starts with a planning phase together with our technologist, who specifies the requirements in size and shape of the mold so it later can be well used for production. Depending on the further processing, like either usage of the molds in starch or otherwise maybe in combination with vacuum forming the shape has different demands that have to be determined. After that the actual designing process in the 3d-program starts and afterwards the mold is printed for a first time.TEST AND TASTE

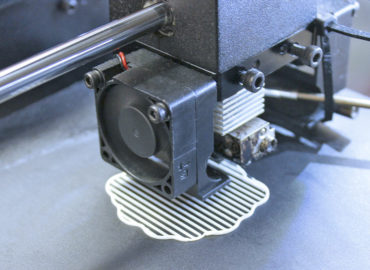

One big advantage of 3D is its flexibility. Templates can be printed again and again as often as you need it for your tries. After each print our technologists can do sensory tests directly on the product, try out e.g. how tall the product has to be, so that it tastes best. On the computer you can easily do adjustments concerning size, thickness or shape. You are free to make different iterations and create a finely tuned product.

PROTOTYPING

3D printing offers even a further field of usage: We can create prototypes of a product to find the right size and shape to fit in a certain packaging. Often you have a given size of an outer packaging and need the right arrangement for a mold as e.g. a vacuum formed insert. By printing a 3D-Dummy of your product, you can do several tries again within short time. You can easily print as many iterations as you need to find the optimum size or arrangement of your product in a packaging. This technique helps you accelerate your whole product development.

INDIVIDUALITY AT A HIGH LEVEL

Thanks to 3D printing you get more freedom to create your product. You can easily design as you want, from a simple to a complex model and adjust whenever you want. We invite you to get in touch with us and develop your own 3D shaped confectionery with us ready for the market. Beginning with finding the right shape, over performing sensory tests and testing the molds at our pilot units, until finally create a product matching exactly your expectations.

Hungry for more?

We feel happy to create your own 3D shaped confectionery